INDUSTRIAL PRESSURE OVENS

VERINOX MHP CU OVENS

- PROCESSES

COOKING

COOKING COOLING

COOLING DESICCATION

DESICCATION DRYING

DRYING PACKAGING REMOVING

PACKAGING REMOVING PASTEURIZATION

PASTEURIZATION ROASTING

ROASTING SMOKING

SMOKING SUPER PASTEURIZATION

SUPER PASTEURIZATION Sanificazione

Sanificazione

- APPLICATIONS

CHEESE

CHEESE FISH

FISH FRUIT

FRUIT MEAT AND COLD CUTS

MEAT AND COLD CUTS No food

No food Pet food

Pet food READY MEALS

READY MEALS VEGETABLES

VEGETABLES

- TYPE OF PLANT

CONTINUOUS

CONTINUOUS INDUSTRIAL

INDUSTRIAL SEMI-CONTINUOUS

SEMI-CONTINUOUS

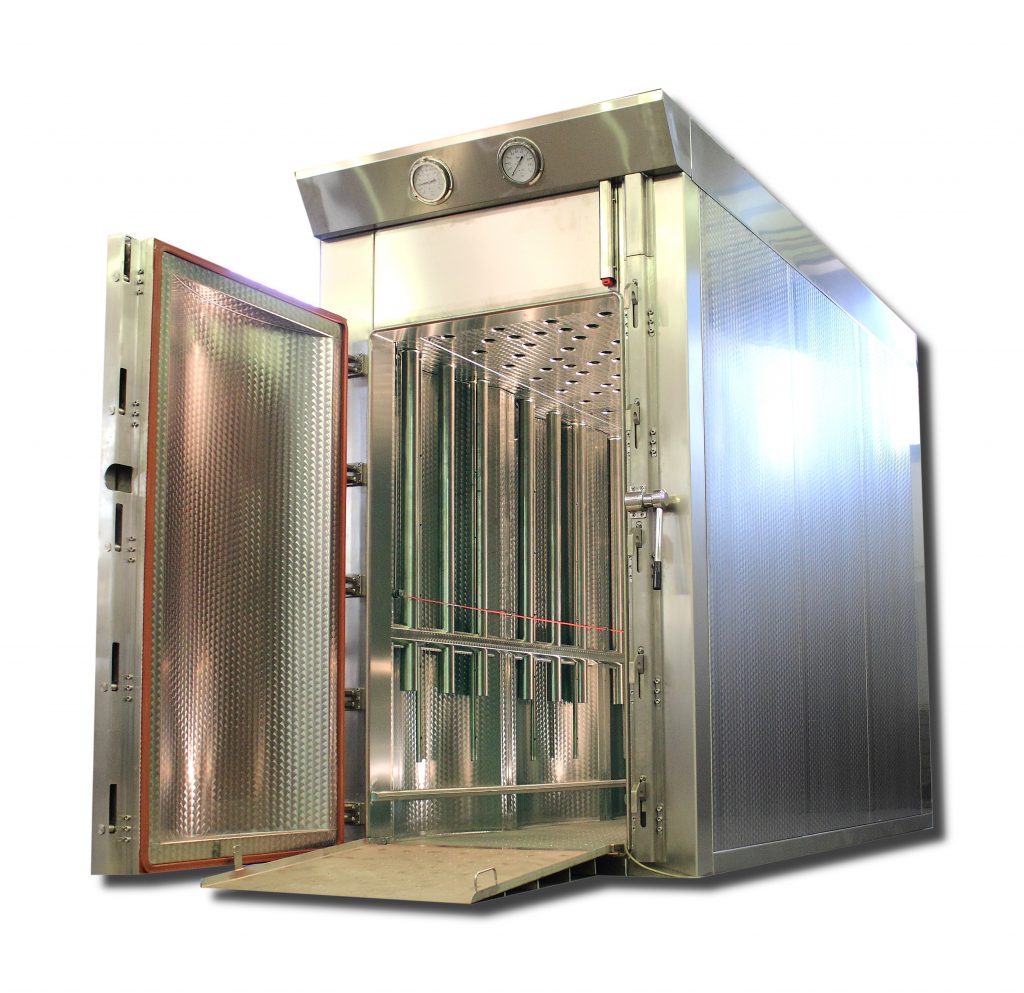

The MHP CU steam oven is an industrial solution with a counter-pressure chamber for cooking and pasteurization, particularly suitable for processing vacuum-packed products or on trays. The characteristics of the machine guarantee a production capacity of up to 10 trolleys, along with the integrity of the packaging, and the taste and appearance of the product. The MHP CU oven also allows traditional steam cooking.

The oven is modular, arranged according to specific industrial production needs and with solutions ranging from the simplest to the most automated for semi-continuous production. You can also choose from different loading possibilities: on wheeled trolleys, racks or conveyors.

Quality and energy efficiency are guaranteed for each machine:

- Special structure, super reinforced

- Increased thermal efficiency and productivity

- Reduced energy consumption in cooking and processing

- Maximum uniformity and effectiveness of heat treatment

- Weight loss reduction

- Reduced bacterial load, increased food safety and shelf life

- Improved organoleptic characteristics

- Uniformity of heat treatment efficiency cycles

COUNTER-PRESSURE FOR COOKING AND PASTEURIZATION

The new generation of ovens is suitable for steam cooking heat treatments in counter-pressure up to 0.5 bar. The rapid and uniform heating, which reaches up to 110°C, is given by the particular steam distribution system in the chamber, the sturdy construction that guarantees the internal overpressure, and the high thickness insulation that preserves heat, limiting dispersion.

All system functions are managed by a personalized control panel, for complete control of the operating cycles.

COUNTER-PRESSURE OVENS PERFORMANCE TEST

| Reduction of steam consumption during cooking and pasteurization | about 67%

|

| Reduced cooking time for ham (can change as per product type) | 20-50% |

| Reduced cooking time for bacon (can change as per product type) | 30-50% |

| Reduced pasteurization time for ham (can change as per product type | about 50% |

| Increased shelf life | about 400% |

| Reduced bacterial load | Close to sterilization |

| Reduced energy consumption during cooling phases (after pasteurization) | about 24% |