AUTOMATIC REMOVAL OF FOOD PACKAGING

VERINOX TNPP TUNNEL

- PROCESSES

COOKING

COOKING COOLING

COOLING DESICCATION

DESICCATION DRYING

DRYING PACKAGING REMOVING

PACKAGING REMOVING PASTEURIZATION

PASTEURIZATION ROASTING

ROASTING SMOKING

SMOKING SUPER PASTEURIZATION

SUPER PASTEURIZATION Sanificazione

Sanificazione

- APPLICATIONS

CHEESE

CHEESE FISH

FISH FRUIT

FRUIT MEAT AND COLD CUTS

MEAT AND COLD CUTS No food

No food Pet food

Pet food READY MEALS

READY MEALS VEGETABLES

VEGETABLES

- TYPE OF PLANT

CONTINUOUS

CONTINUOUS INDUSTRIAL

INDUSTRIAL SEMI-CONTINUOUS

SEMI-CONTINUOUS

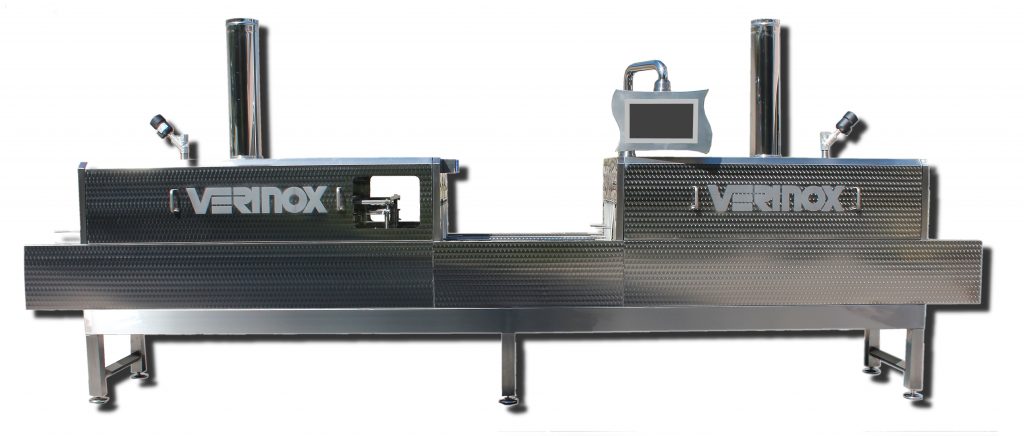

The TNPP tunnel is the innovative solution for the automatic removal of bags and/or skin with surface cleaning of cooked and raw products in a semi-continuous solution.

This machine therefore allows to solve common production problems such as product unpacking and sanitizing.

The integration of this plant within the production sector allows to:

- Automate the removal of the bag or skin

- Reduce labour and processing times

- Sanitize and break down superficial bacterial loads on products

- Have clean products before packaging

- Increase productivity

CHARACTERISTICS OF THE SEMICONTINUOUS TUNNEL

The tunnel for sanitizing food and removing packages or skins has a stainless steel structure, with a conveyor belt in steel mesh complete with an input speed regulator.

The preheating zone is specially designed to direct steam on all areas of the product, extracting the exhausted steam using an upper cowling and an electric fan.

The bag is cut by rotating blades mounted on adjustable arms, specifically designed to achieve maximum precision and to return the product to the operator for manual removal.

The belt is equipped with an automatic water washing cleaning system.

FUNCTIONS OF THE TNPP TUNNEL

The product is loaded onto the belt and enters the tunnel, where the package is heated externally to facilitate removal of the bag or skin. At the exit from the tunnel an automatic blade performs a horizontal cut on the bag to then be transported to the operator.

Continuing on the belt after removal of the bag, the product enters the second part of the tunnel where a series of steam jets removes the gelatin on the surface and sanitizes the product. This enables to have optimal cleaning of the product with minimal exposure to air or other potentially contaminated agents. The product can now be sent directly to the packaging line.