INDUSTRIAL VENTILATED OVEN

VERINOX JUNIOR UNIVERSAL OVEN

- APPLICATIONS

CHEESE

CHEESE FISH

FISH FRUIT

FRUIT MEAT AND COLD CUTS

MEAT AND COLD CUTS No food

No food Pet food

Pet food READY MEALS

READY MEALS VEGETABLES

VEGETABLES

- PROCESSES

COOKING

COOKING COOLING

COOLING DESICCATION

DESICCATION DRYING

DRYING PACKAGING REMOVING

PACKAGING REMOVING PASTEURIZATION

PASTEURIZATION ROASTING

ROASTING SMOKING

SMOKING SUPER PASTEURIZATION

SUPER PASTEURIZATION Sanificazione

Sanificazione

The Junior universal ventilated oven for small and medium production series is a combined solution with forced ventilation for dry cooking heat treatment, drying, roasting and smoking. Furthermore, steam cooking is also possible thanks to an autonomous steam production system.

Suitable for all types of food, this universal oven guarantees the following:

- Maximum cooking uniformity and efficiency

- Rapid heating

- Optimization of cooking times

- Ease of use

- Low energy consumption

CHARACTERISTICS OF THE UNIVERSAL OVEN

The excellent uniformity and high speed heating up to 180°C of the universal Junior oven is guaranteed by stainless steel impellers and special armoured electric resistors. The overall structure is insulated with a high insulating foamed material, covered with decorated and satin-finished stainless steel panels.

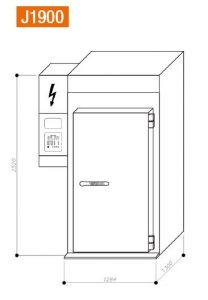

| J1900 MODEL | J1100 MODEL | |

| WIDTH | 129 cm | 100 cm |

| LENGTH | 130 cm | 98 cm |

| HEIGHT | 252 cm | 199 cm |

| TROLLEY CAPACITY | 1 | 1 |

| LOADED NET LIGHT | 100×193 cm | 88×147 cm |

| TROLLEYS | 88x98x198h cm | 73x76x144h cm |

INTEGRATED CONTROL SYSTEM

This ventilated oven is designed to manage continuous work cycles, 24 hours a day. For this reason we have integrated an electronic control panel to program recipes and automatic operation.

The microprocessor panel is a highly technological, simple and reliable instrument: it shows the time and working temperature, the progression of the phases in progress and the position of the dampers. Furthermore, from this control point you can set ventilation, pass from one phase to another and delay start-up.